Project Description

Engineering Wise was entrusted with a critical project to fabricate and repair high-pressure pipelines for a major oil and gas processing facility. This project required advanced welding techniques and strict adherence to international safety standards, given the high-stakes environment of oil and gas operations. Our team of expert welders, armed with cutting-edge tools and materials, delivered a solution that ensured long-term durability and safety.

Challenges Faced by the Client

- The client’s existing high-pressure pipeline system had suffered from wear, corrosion, and stress fractures, leading to safety concerns and reduced efficiency in operations.

- Any repairs or fabrication work risked halting operations, which could result in significant revenue loss. The client needed a solution that minimized disruptions and allowed production to resume as quickly as possible.

- Operating in the oil and gas sector, the client was required to meet rigorous international safety and quality standards, such as API 1104 and ASME. Ensuring compliance while maintaining efficiency was a constant challenge.

- During the assessment phase, previously undetected damage in the pipeline system was discovered, which expanded the scope of repairs beyond initial expectations. This posed additional financial and logistical challenges for the client.

- High-quality, durable materials were needed for pipeline fabrication and repairs, but sourcing these materials on short notice could be difficult. This was further complicated by the facility’s specific operational needs and safety requirements.

- Certain sections of the pipeline were located in hard-to-reach areas, making inspection, repair, and fabrication work particularly challenging. The client faced difficulties maintaining these sections of the infrastructure without specialized solutions.

- Operating in a high-risk environment with flammable materials required the client to prioritize safety at every stage. Welding and repair work needed to be executed with the utmost care to prevent accidents or failures.

- The facility’s location exposed it to extreme weather conditions, which complicated repair timelines and increased the risk of equipment or infrastructure damage during maintenance work.

Key Scope Elements

- Design and construct high-pressure pipelines to connect critical units within the processing facility.

- Use precision welding techniques to ensure the structural integrity and reliability of the new pipeline network.

- Source and utilize high-grade materials such as stainless steel and alloy steel to meet operational demands.

- Identify areas of wear, corrosion, and damage in the existing pipeline system.

- Apply welding techniques to repair cracks, reinforce weak points, and prevent potential failures.

- Conduct protective coating applications post-repair to enhance corrosion resistance.

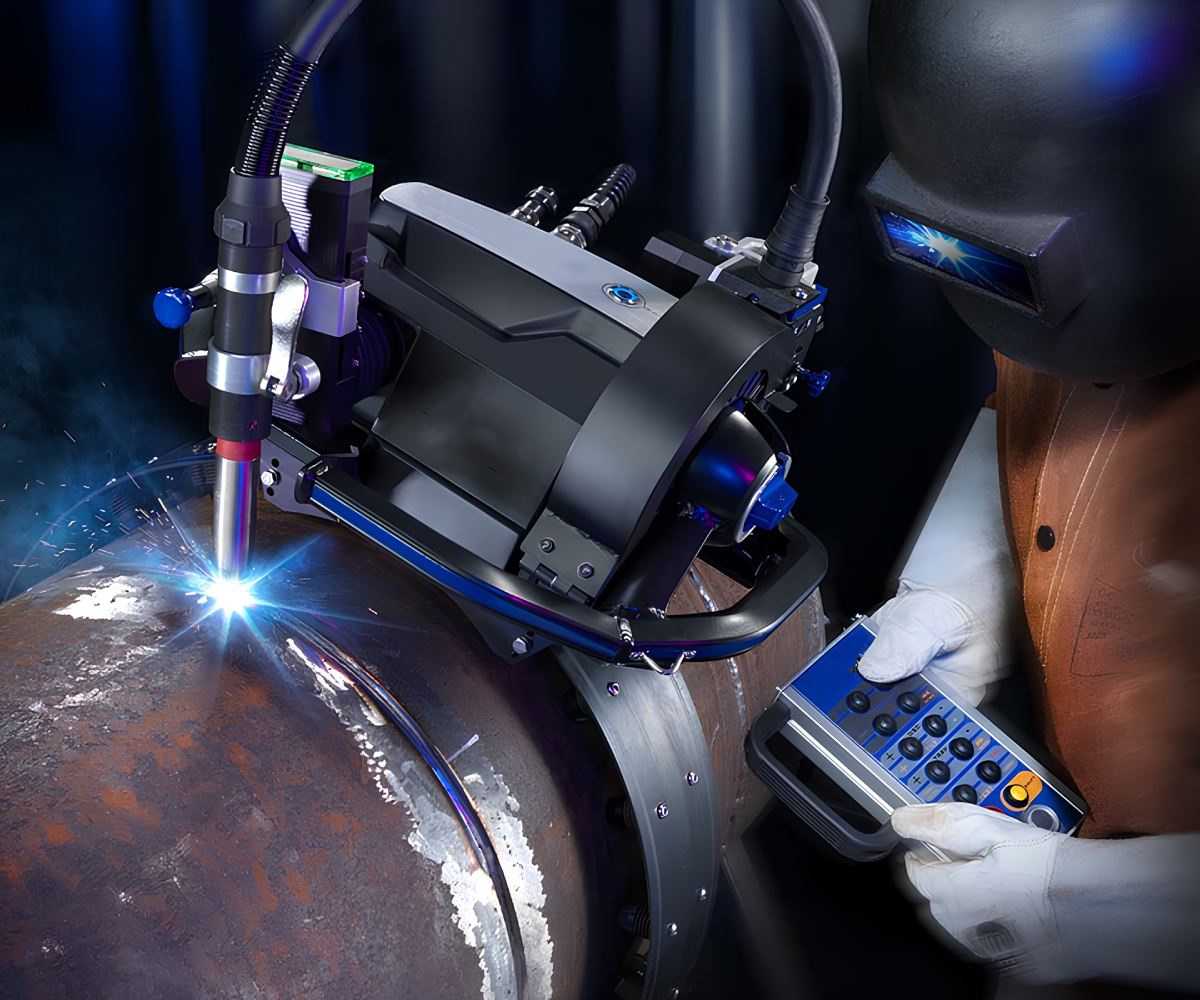

- GTAW (TIG Welding): For precise, high-quality welds in critical and high-stress areas.

- SMAW (Stick Welding): For reliable field repairs in challenging environments.

- FCAW (Flux-Cored Arc Welding): For rapid and durable welding in larger, less accessible areas.

- Perform inspections such as radiographic testing, ultrasonic testing, and dye penetrant testing to ensure weld quality and detect hidden flaws.

- Validate all welds for compliance with API 1104, ASME, and other international safety standards.

- Work with high-pressure grade materials suitable for oil and gas operations.

- Ensure proper storage, handling, and preparation of materials to maintain integrity during welding.

- Implement rigorous safety protocols to protect workers, assets, and the environment.

- Follow strict quality assurance procedures to meet or exceed international safety and performance standards.

- Develop and adhere to a strict project timeline to minimize disruption to ongoing operations.

- Employ an efficient workflow to complete repairs and fabrications within the agreed-upon schedule.

- Provide detailed documentation, including welding records, NDT results, and compliance certifications.

- Deliver a final report outlining work completed, testing outcomes, and recommendations for ongoing maintenance.

Solutions Implemented to Overcome Challenges

- Solution: Utilized precise site assessments and coordinated with the client to schedule work during low-traffic hours to minimize disruptions.

- Established clear communication between the welding team and other operational staff to ensure safety and efficiency when working near active pipelines and equipment.

- Used specialized portable equipment, such as compact welding units, to access confined spaces and execute repairs in areas with limited movement.

- Solution: Equipped the team with weather-resistant gear and implemented climate-controlled welding tents to regulate temperature and prevent welding defects due to environmental conditions.

- Incorporated heaters for equipment and protective covers for welding areas to maintain optimal working conditions during adverse weather.

- Solution: Implemented stringent quality assurance protocols, including continuous monitoring of welding temperatures and pressures to ensure the integrity of the high-pressure pipelines.

- Used high-grade consumables and advanced welding techniques like TIG (GTAW) and SMAW to ensure flawless welds capable of handling high-pressure operations.

- Employed certified welders and inspectors to ensure compliance with safety regulations at every stage of the project.

- Solution: Organized the project into phases, focusing first on the most critical areas that would have the greatest impact on the client’s operations.

- Increased workforce efficiency by deploying additional skilled welders and support personnel, allowing for multiple shifts to accelerate the repair and fabrication processes.

- Used advanced project management tools to closely monitor progress, ensuring all tasks were completed on time without compromising quality.

- Solution: Established strong relationships with trusted suppliers to source high-grade materials swiftly. In cases of material shortages, alternative solutions were identified without compromising safety or quality standards.

- Worked closely with the client to confirm material specifications, ensuring compliance with both regulatory standards and operational needs.

- Solution: Set up a dedicated quality control team to monitor and inspect all welding work against international standards, including API 1104 and ASME.

- Conducted regular in-house and third-party testing (radiographic, ultrasonic, and visual inspections) to verify the integrity of each weld before the pipeline was returned to service.

- Created detailed documentation for each weld, including NDT reports and certifications, to provide the client with a full compliance record.

- Solution: Used custom-built scaffolding and mobile welding rigs to reach difficult-to-access areas.

- Applied advanced robotic welding technology for precise repairs in confined spaces where manual welding was not feasible.

- Ensured a flexible, adaptable approach, repositioning equipment and personnel to maximize workspace and minimize risks.

- Solution: Immediately adjusted the project scope upon discovering additional damage. Coordinated with the client to extend the timeline and budget to include the new repairs.

- Reassigned resources to address the newly discovered issues quickly, ensuring no significant delays occurred in the overall project.

- Utilized advanced leak detection and imaging technologies to identify hidden damage early on, preventing future surprises.

Outcome of Solutions

These targeted solutions enabled Engineering Wise to overcome each challenge effectively, ensuring the project was completed on time, within budget, and to the highest safety and quality standards. The oil and gas processing facility was able to resume normal operations without significant downtime, and the newly fabricated and repaired pipelines met all operational and regulatory requirements.

Client Feedback

We were particularly impressed with their ability to meet tight deadlines while ensuring compliance with international standards such as API 1104 and ASME. Their proactive approach in managing unforeseen issues, sourcing materials quickly, and maintaining continuous communication throughout the project made all the difference.

Thanks to Engineering Wise, we now have a fully functional pipeline system that meets our high safety and performance requirements. The work was completed on schedule, and we’ve seen an improvement in the overall efficiency of our operations. We look forward to continuing our partnership for future projects.”

— Maintenance Manager, Oil & Gas Processing Facility